NIPPON YUKA KOGYO >> Cold flow property improver

Cold flow property improver

Product name |

Application |

Effect |

Package |

Wax Breaker |

Improvement for cold flow The standard dosing rate: 1/2000 |

It prevents strainer blockage and solidification of paraffin wax included in fuel oil of storage tank caused by MGO and MDO with poor cold flow properties in cold areas. |

18L CAN |

obtained the product certification by NIPPON KAIJI KYOKAI (ClassNK) >> " Certification"

In recent years, there is a concern for fuel oil with paraffin wax (long chain linear hydrocarbons etc.).

Paraffin wax precipitates as solid crystals in fuel oil at low temperatures, this follows that the fluidity of fuel oil is lost.

Such cold flow property phenomenon is found in distillates such as MGO and MDO. If this occurs in a storage tank or in a strainer and or purifier, it becomes difficult to transfer the fuel oil.

Wax Breaker is a fuel oil additive for solving issues as shown above.

The paraffin wax is substances of a nature that solidifies as it cools like a candle wax.

The paraffin wax component contained in the fuel oil is derived from crude oil and fractions to be blended.

The standard dosing rate is 1/2000 (The recommend dosing rates are ranging from 1/2000 to 1/500)

*The standard dosing rate is assuming usage situation at minimum temperature of "5 ° C" in engine room.

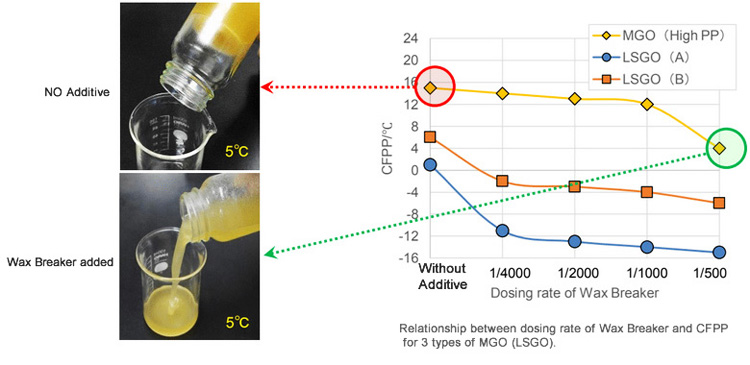

1) Improvement effect of CFPP (Cold Filter Plugging Point)

Wax Breaker can improve the CFPP of various MGO (LSGO) and MDO to 5 °C or less at the dosing rate is 1/2000 ~ 1/500 (500 ~ 2000 ppm).

When dosing rate of Wax Breaker is 1/500, CFPP of MGO (with very high Pour Point) is improved from 16 °C to 4 °C, it will prevent from blockage at storage tank, strainer and purifier.

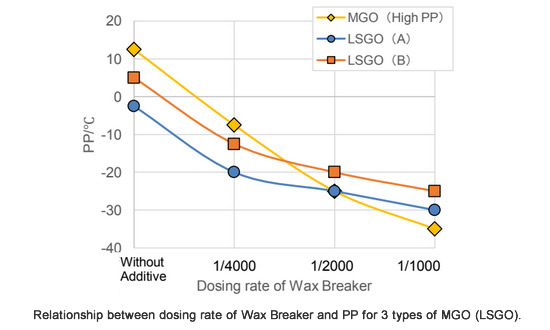

2) Improvement effect of PP (Pour Point)

Wax Breaker can improve the PP of various MGO (LSGO) and MDO to minus 10 °C or less at the dosing rate is 1/2000 (500 ppm).

By improving PP, Wax Breaker will prevent fuel oil solidification in storage tank, it can be possible to transfer MGO and MDO with poor cold flow properties to the engine room from the storage tank in cold areas.

Please feel free to contact us if you are interested with cold flow properties of fuel oil or have any problems regarding the fuel oil with poor cold properties.